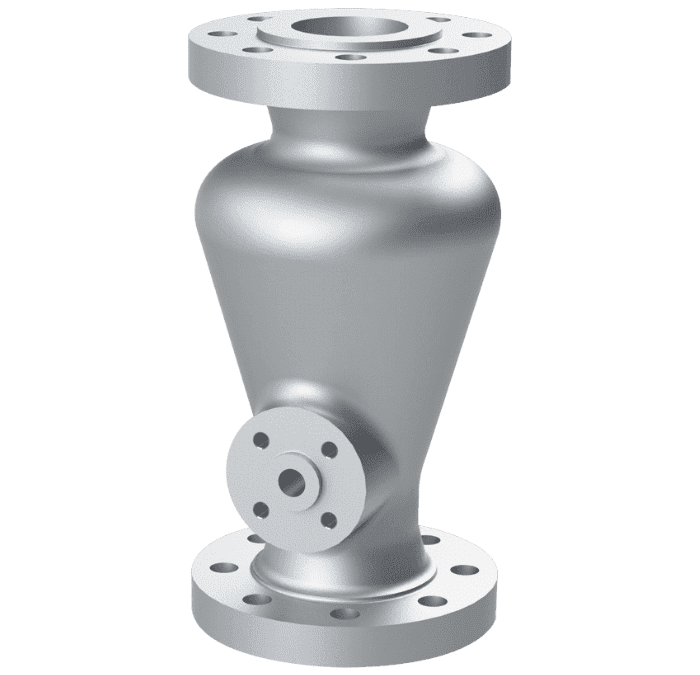

Variable orifice desuperheater

One of the most innovative desuperheater product on the market, the IMI CCI AB5900 standard desuperheater incorporated 50 years of experience and lesson-learnt to increase plant performance in a robust compact design with high reliability.

The AB5900 desuperheater performance is exceptional at low steam velocity with high temperature control accuracy and operating near saturation point. Combine this with the highest available rangeability of steam flow the AB5900 desuperheater provides the flexibility needed to increase plant efficiency and productivity.

The AB5900 desuperheater is a robust compact design able to achieve complete evaporation with the shortest straight-pipe distance of just 1 meter and less than 5.5 meters of distance required to the temperature sensor. With a long history of installation, the AB5900 desuperheater is a proven reliable solution.

The enhanced features of the AB5900 desuperheater ensure complete evaporation in the shortest pipe distance for stable and accurate temperature control in high rangeability applications.

Flow-plug – Cooling water is ejected as a fine spray by high velocity steam flowing between the plug and nozzles. The flow-plug provides variable orifice area to maintain high velocity steam flow around the seat. The steam velocity is controlled by the rising flow-plug with optimum control for high rangeability. Seat ring with spray nozzle- – The seat ring with spray nozzle assists in circulating the spray water evenly around the annular passage. Upper body chamber- – High fluid turbulence in the upper body chamber increases the mixing efficiency, allowing time for the complete spray water evaporation in the shortest pipe distance.

More info : https://www.imi-critical.com/products/ab5900/